PTFE (Polytetrafluoroethylene) heat shrink tubing is a high-performance, fluoropolymer-based protective sleeve designed to provide exceptional insulation, chemical resistance, and temperature tolerance. Thanks to its strong carbon-fluorine molecular structure, PTFE remains stable under extreme thermal, electrical, and chemical conditions. When exposed to heat (typically above 350°C), the tubing shrinks radially to form a tight, secure covering over the target component, offering advanced insulation, corrosion protection, and mechanical strength. PTFE heat shrink tubing is widely used in industries such as aerospace, defense, medical, electronics, power systems, and telecommunications.

PTFE (Polytetrafluoroethylene) heat shrink tubing is a high-performance, fluoropolymer-based protective sleeve designed to provide exceptional insulation, chemical resistance, and temperature tolerance. Thanks to its strong carbon-fluorine molecular structure, PTFE remains stable under extreme thermal, electrical, and chemical conditions. When exposed to heat (typically above 350°C), the tubing shrinks radially to form a tight, secure covering over the target component, offering advanced insulation, corrosion protection, and mechanical strength. PTFE heat shrink tubing is widely used in industries such as aerospace, defense, medical, electronics, power systems, and telecommunications.

Structure & Types

Material: 100% pure PTFE (Polytetrafluoroethylene)

Construction: Semi-rigid, military-grade, capable of providing stable and consistent coverage

Shrink Ratio: Standard options include 1.7:1 and 4:1

Wall Thickness: Available in standard thin-wall and thick-wall formats; post-shrink wall thickness can exceed 0.2mm

Color Options: Transparent by default, with custom options such as black, red, blue, yellow, and green

Length Options: Available in cut-to-length segments or spooled formats

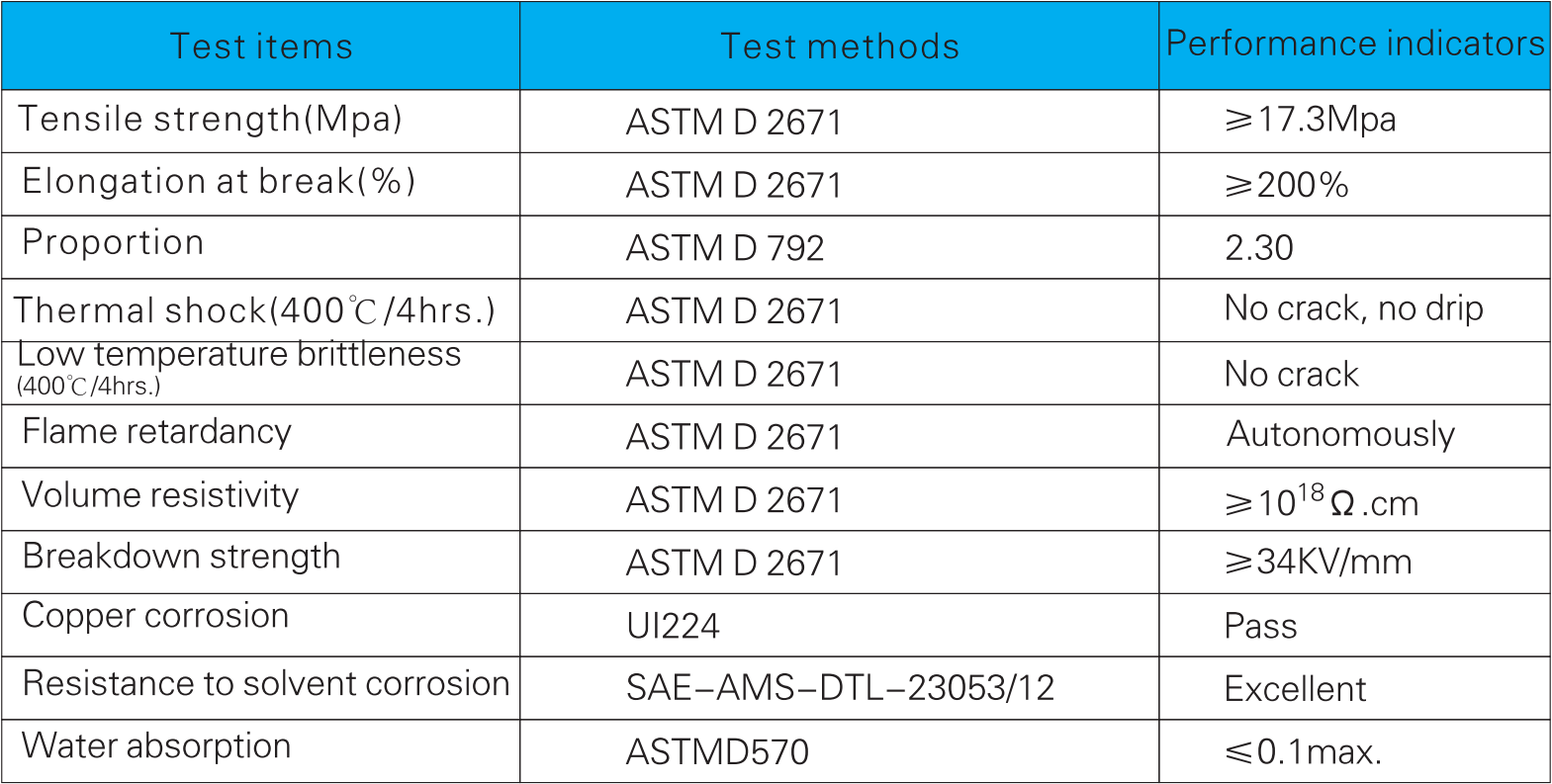

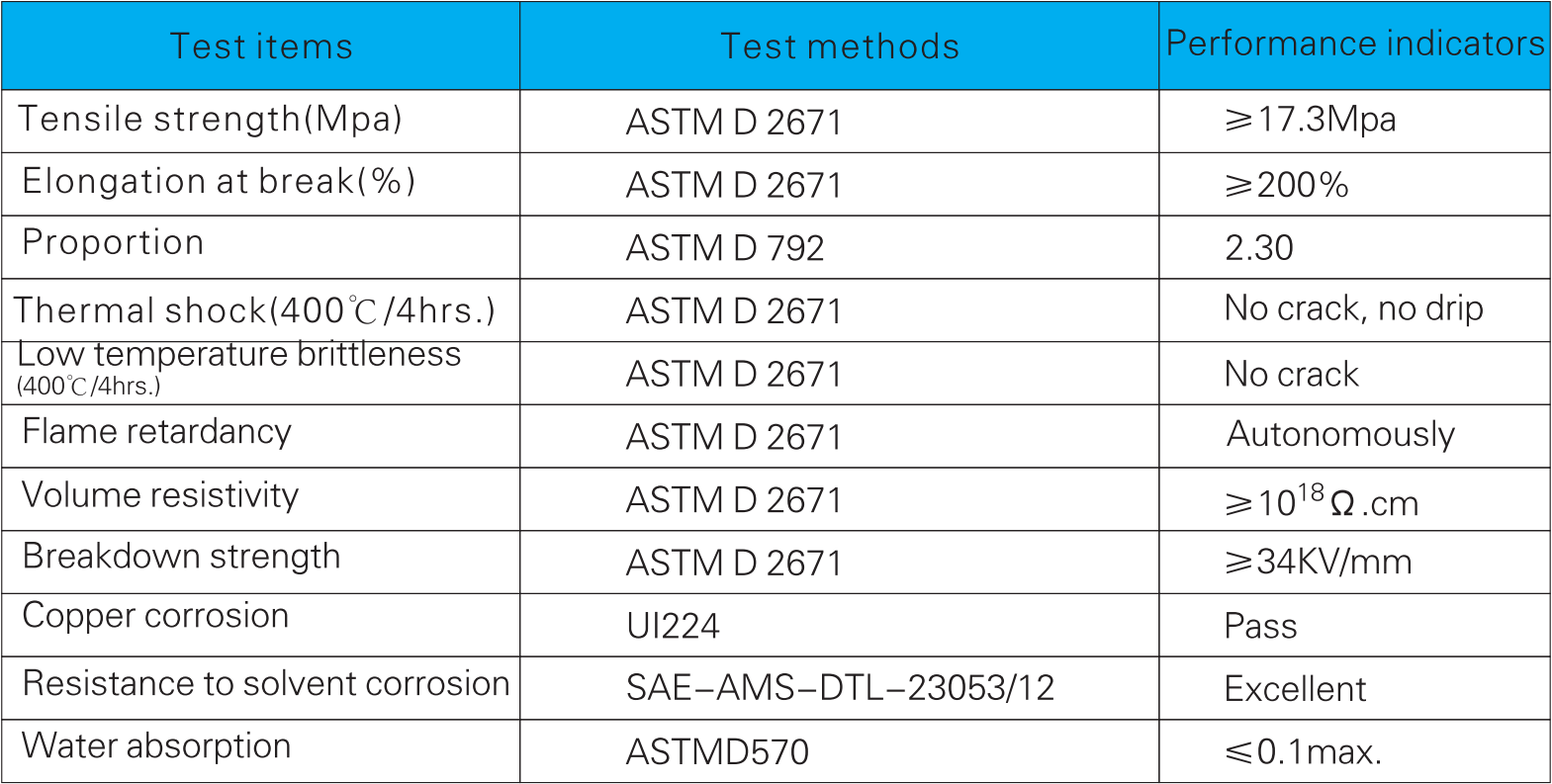

Specification

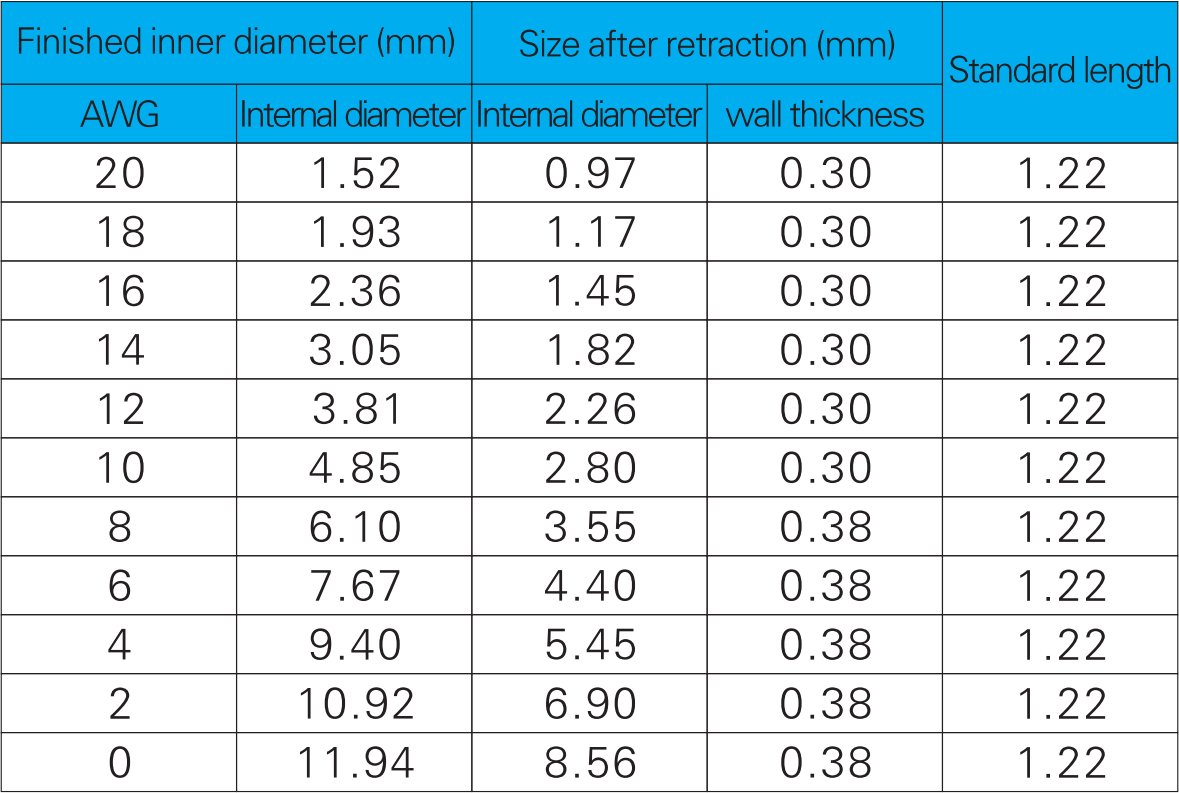

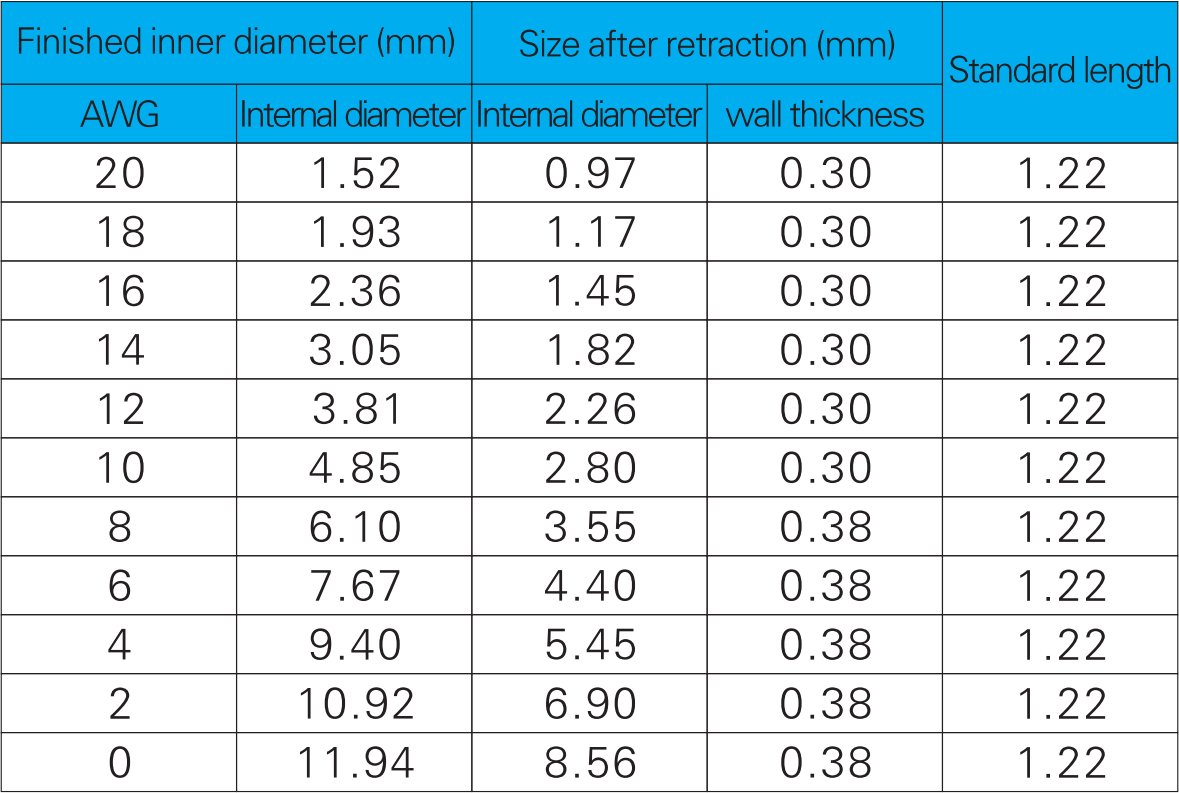

Dimension 1(1.7:1)

Dimension 2(4:1)

Key Advantages

Outstanding Thermal Resistance: Operates continuously at up to 260°C; short-term peaks up to 300°C

Excellent Electrical Insulation: Extremely high resistivity ensures safe and stable performance in critical circuits

Superior Chemical Inertness: Unaffected by most industrial chemicals, including strong acids and bases

Low Friction Coefficient: Natural self-lubricating property reduces wear between components

Anti-Aging and UV Resistance: Performs reliably outdoors and under prolonged sunlight exposure

Halogen-Free & Eco-Friendly: Non-toxic, compliant with RoHS and REACH standards, ideal for medical and food-grade applications

Industry Applications

Aerospace

Used for insulation and chemical protection of high-temperature sensor cables, wire harnesses, and connectors in engines and aircraft interiors.

Electrical & Electronics

Protects transformers, electric motors, circuit boards, and cable terminations from arc faults, short circuits, and chemical damage.

Medical Equipment

Ideal for ECG monitors, endoscopic instruments, and surgical devices due to its biocompatibility and sterilization compatibility.

Telecommunication

Ensures insulation and signal integrity in fiber optics, coaxial cables, and high-frequency data lines.

Automotive

Extensively used in high-voltage cable protection in EVs and internal combustion vehicles, especially near engines and batteries due to oil and fuel resistance.

Chemical and Laboratory

Applied in lab and industrial environments for corrosion-resistant cable protection in highly acidic or alkaline conditions.

Application Case Studies

An aerospace parts supplier used PTFE heat shrink tubing to enhance sensor wire harness performance, reducing failures from corrosion and thermal cycling.

A leading medical device manufacturer adopted PTFE tubing for internal electrical connections in surgical equipment, meeting FDA-grade cleanliness standards.

In electric vehicle production, PTFE tubing was implemented in battery pack cable assemblies to improve thermal and electrical safety performance.

FAQ

Is PTFE heat shrink tubing suitable for outdoor, high-temperature environments?

Yes. PTFE offers excellent resistance to weathering and UV light, making it ideal for long-term outdoor applications in harsh conditions.

How does PTFE compare to FEP and PFA heat shrink tubing?

PTFE has the highest heat resistance (up to 260°C), whereas FEP and PFA offer easier processing but lower temperature limits. PTFE is better suited for the most demanding applications.

Can I request custom sizes or colors?

Absolutely. Custom shrink ratios, inner diameters, wall thicknesses, lengths, and colors can be manufactured to meet your project requirements.

Is there any odor or toxicity during heat shrinking?

Genuine PTFE tubing produces little to no odor during proper heating. It is non-toxic and safe when used within recommended temperature limits.

Do you offer samples and technical support?

Yes. Free samples and expert support are available to help you select the most suitable product model and configuration for your application.

English

English