Adhesive Lined Heat Shrink Tubing and Adhesive Heat Shrink Sleeving are essential solutions for enhancing the durability, insulation, and waterproofing of wires and cables in a variety of industries. Designed with a dual wall construction, these heat shrink products offer superior sealing properties and long-lasting protection against environmental elements. Whether you're working in automotive, electrical, marine, or industrial applications, our high-performance heat shrink tubing and sleeving products ensure optimal performance and reliability.

What is Adhesive Lined Heat Shrink Tubing?

Adhesive Lined Heat Shrink Tubing is a versatile product that combines heat shrink technology with an adhesive lining, ensuring an excellent bond to wires, cables, and other components. When heat is applied, the tubing contracts tightly, and the adhesive melts, creating a waterproof, durable, and secure seal. It’s ideal for applications requiring extra insulation, protection from moisture, and reliable electrical connections.

Key Features of Adhesive Lined Heat Shrink Tubing:

Waterproofing & Sealing: The adhesive lining ensures a waterproof barrier that protects wires and cables from water, oils, and other contaminants. It is perfect for applications exposed to harsh conditions, like marine and automotive wiring.

Durability & Protection: This tubing offers high resistance to mechanical wear, abrasion, and chemicals, making it highly durable in industrial environments. It is perfect for preventing corrosion and ensuring the longevity of your cables and connections.

Temperature Resistance: With a high temperature tolerance, adhesive lined heat shrink tubing can withstand a wide range of temperatures, making it suitable for high-temperature applications. It provides exceptional heat resistance, ensuring reliable performance in extreme conditions.

Flexible & Easy to Install: Designed for ease of use, this tubing is flexible and can be applied with standard heat-shrinking methods, such as a heat gun or oven. Its high shrink ratio makes it suitable for a variety of applications with different wire and cable sizes.

Flame Retardant Properties: This tubing also has flame-retardant qualities, ensuring it provides safety in environments where heat or flame exposure may occur, such as automotive and electrical wiring systems.

Applications of Adhesive Lined Heat Shrink Tubing:

Automotive Wiring & Electrical Systems: Protects electrical connections from moisture, salt, and chemicals commonly found in automotive environments.

Marine Applications: Ideal for boat wiring, it seals connectors and terminals to protect them from water exposure, preventing corrosion and enhancing longevity.

Electrical & Industrial Wiring: Ideal for sealing and insulating electrical wiring in high-temperature or harsh environments, such as manufacturing plants, power plants, and heavy machinery.

Consumer Electronics: Used for securing wires in electronic devices, ensuring that they are insulated from moisture and contaminants.

Home & Outdoor Applications: Protects wires and cables for lighting systems, outdoor electrical applications, and household appliances exposed to elements.

Why Choose Adhesive Heat Shrink Sleeving?

Adhesive Heat Shrink Sleeving offers all the benefits of adhesive lined heat shrink tubing but in a sleeker, sleeving form that is often used to bundle cables together, providing additional protection and insulation. Its unique design allows it to cover multiple wires simultaneously, offering seamless protection against electrical interference and environmental factors.

Key Features of Adhesive Heat Shrink Sleeving:

Enhanced Bonding and Sealing: With the adhesive layer, it ensures that cables or wires are completely sealed, offering excellent protection against water, dust, and moisture.

Strong Mechanical Protection: The sleeving offers excellent protection against abrasion, reducing wear and tear on sensitive cables and connections.

Wide Range of Sizes: Available in various diameters to accommodate different cable bundles, ensuring a tight, secure fit for your needs.

Ease of Installation: Similar to heat shrink tubing, the sleeving shrinks when heated, and the adhesive melts to bond the sleeve to the cable, making installation straightforward.

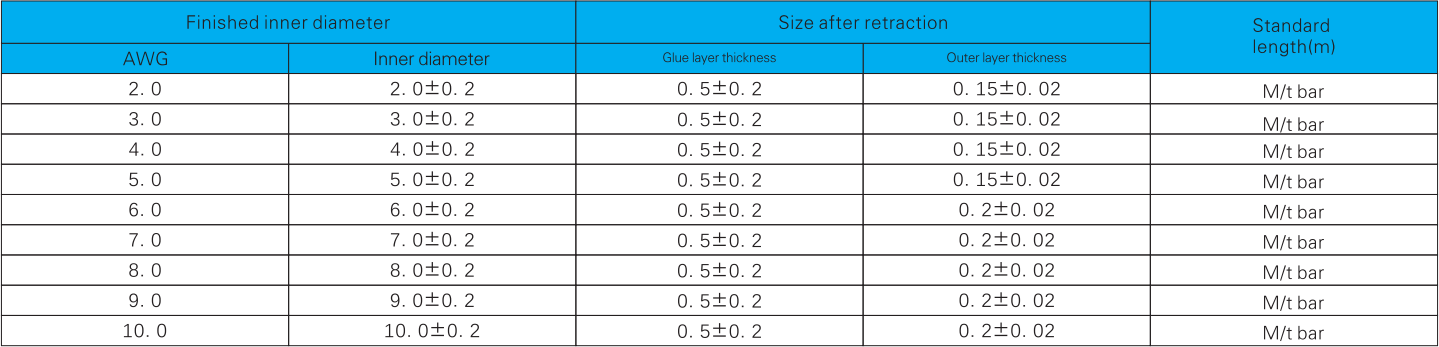

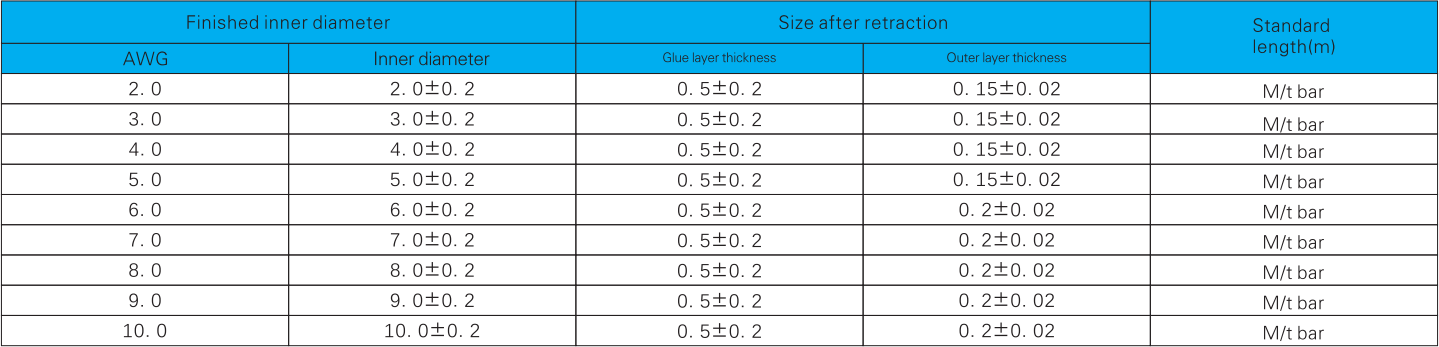

Dimension

Applications of Adhesive Heat Shrink Sleeving:

Wire Bundling & Protection: Ideal for bundling wires in applications such as electrical panels, circuit boards, and other complex electrical systems.

Automotive & Marine Wiring: Provides added protection to multi-wire cables, ensuring protection against the elements and wear.

Industrial Equipment: Perfect for protecting cable assemblies and wire harnesses in industrial machinery and equipment.

Custom Adhesive Lined Heat Shrink Tubing & Sleeving

We also offer custom solutions for adhesive lined heat shrink tubing and sleeving. Our team can create tailored products that meet your exact specifications, including custom diameters, lengths, and adhesive types to suit your unique needs. Whether you’re working on a large-scale industrial project or small-scale electronic applications, we have the solution for you.

Key Advantages of Custom Solutions:

Perfect Fit: Custom sizes to fit your unique wire and cable requirements.

Enhanced Performance: Tailored adhesive formulas for specific environments, ensuring optimal sealing and insulation.

Increased Efficiency: By providing exactly what you need, you can reduce waste and increase installation efficiency.

Why Choose Us for Your Adhesive Lined Heat Shrink Tubing & Sleeving Needs?

High-Quality Materials: Our tubing and sleeving products are made from premium materials designed to withstand extreme conditions, ensuring reliability and longevity.

Fast Delivery & Large Inventory: With our extensive inventory, we offer fast and reliable shipping to meet your project deadlines.

Competitive Pricing: We offer cost-effective solutions without compromising on quality, helping you stay within budget while achieving superior performance.

Expert Support: Our knowledgeable team is ready to assist with product selection, customization, and any technical queries you may have.

Usage

Military standard, semi hard, flameretardant, long-term use at 350 ℃Cresistant to almost al oils and chemicals

Characteristics

Shrinkage ratio: 1.7:1

Shrinkage temperature: 350 ℃C

Operating temperature:-65 ℃℃~350℃CWithstand voltage level: 600V

Environmental protection standard: RoHS compliant

Color: transparent (normal)Product specifications:2.0~10.0

Specification

It is made of polytetrafluoroethylene and meets the requirements of SAE-AMS-DTL-23053/13 military standard.It can be used at hightemperature of 350 'C for a long time.lt is resistant to almost all oils andchemicals.lt is used in situations that require ultra-high temperature resistance and chemical resistance,as well as great requirements for electrical in sulation and highflame resistanceIt is widely used in automobile, military, aerospaceand other fields.

FAQ:

1. What is Adhesive Lined Heat Shrink Tubing?

Adhesive Lined Heat Shrink Tubing is a type of heat shrink tubing that has an internal adhesive lining. When heat is applied, the tubing shrinks tightly around the component, and the adhesive melts to bond securely to the surface, providing a moisture-tight, durable seal.

2. What are the key benefits of using Adhesive Lined Heat Shrink Tubing?

The key benefits include superior sealing and insulation, moisture resistance, protection against chemicals, abrasion, and extreme temperatures, and a durable, long-lasting bond. It also prevents corrosion and ensures electrical safety.

3. How does Adhesive Lined Heat Shrink Tubing work?

When heat is applied to the tubing, it shrinks to fit tightly around the component. At the same time, the adhesive lining melts and bonds to the underlying surface, providing a secure and waterproof seal.

4. Where is Adhesive Lined Heat Shrink Tubing commonly used?

It is commonly used in electrical applications, automotive wiring, marine environments, industrial machinery, and military systems. It is ideal for use in areas that are exposed to moisture, oils, chemicals, or extreme temperatures.

5. What is the difference between Dual Wall and Single Wall Heat Shrink Tubing?

Dual Wall Heat Shrink Tubing features both a shrinkable outer layer and an internal adhesive layer that melts to create a bond. Single Wall Heat Shrink Tubing only shrinks and does not have an adhesive layer.

English

English