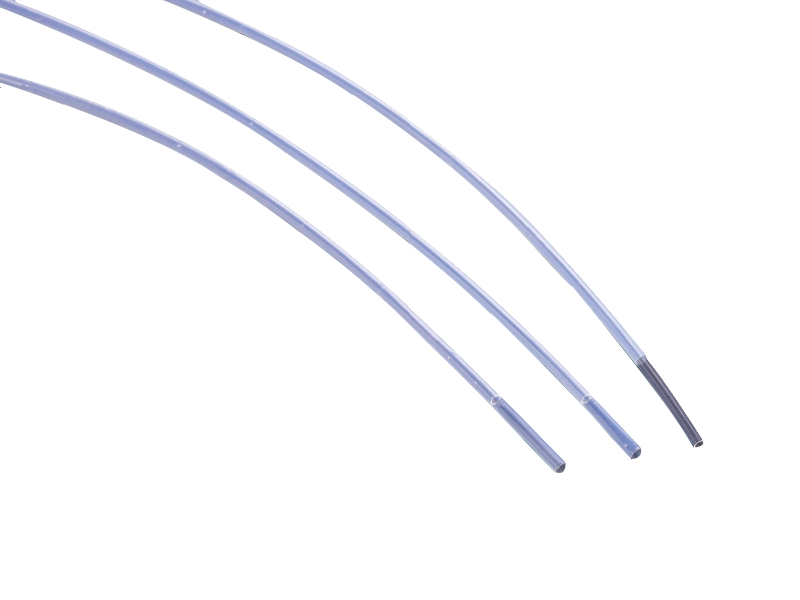

Heat Shrink Tubing is a versatile solution for insulation, protection, and identification of electrical wires, cables, and components. Also known as Heat Shrink Sleeving or Heat Shrink Tube, it provides a durable, protective layer that shrinks tightly over wires or components when heat is applied.

High-performance versions, such as Ul Heat Shrinkable Sleeve and High-Temperature Heat Shrink Tubing, are engineered for demanding applications in electronics, automotive, aerospace, and industrial sectors. Adhesive Lined Heat Shrink Tubing and Adhesive Lined Heat Shrink Sleeve ensure a watertight seal and enhanced mechanical strength, making them ideal for harsh environments.

Key Features & Advantages

Durable Protection – Shields wires and cables from abrasion, moisture, chemicals, and UV exposure.

Reliable Insulation – Prevents short circuits and electrical failures by providing high-quality insulation.

Adhesive Lined Options – Adhesive Lined Heat Shrink Tubing creates a tight seal, offering additional mechanical strength and waterproofing.

High-Temperature Resistance – High-Temperature Heat Shrink Tubing withstands extreme operating temperatures, maintaining shape and function.

Versatility – Available in various diameters, shrink ratios, and materials for multiple industrial, electrical, and automotive applications.

Technical Highlights

Material Options: Polyolefin, PVC, PTFE, and other specialized polymers.

UL Certification: Ensures compliance with international safety standards.

Shrink Ratios: 2:1, 3:1, 4:1 for different application needs.

Adhesive Lining: Provides sealing against moisture, chemicals, and vibration.

Operating Temperature Range: Standard 90°C–125°C, high-temperature versions up to 260°C.

Applications

Electrical insulation for wires, cables, and terminals

Wire bundling and identification

Waterproof sealing for automotive connectors and electronic components

Aerospace and industrial equipment requiring high-temperature resistance

Protection of sensitive components in harsh chemical environments

Why Choose Our Heat Shrink Tubing?

High Quality – Made from premium materials with strict quality control for reliable performance.

Wide Selection – Heat Shrink Tube, Ul Heat Shrinkable Sleeve, and Adhesive Lined Heat Shrink Sleeve available in multiple sizes and shrink ratios.

Enhanced Safety – UL-certified tubing ensures compliance with electrical safety standards.

Durability & Longevity – Resistant to abrasion, chemicals, and high temperatures.

Customized Solutions – Can provide adhesive lined heat shrink tubing and sleeves tailored to specific industrial requirements.

FAQ

Q1: What is heat shrink tubing used for?

A1: It is used to insulate, protect, and bundle wires, cables, and electronic components, providing electrical safety and mechanical protection.

Q2: What are the benefits of adhesive lined heat shrink tubing?

A2: Adhesive lined tubing provides a watertight seal, additional mechanical strength, and resistance to vibration and chemical exposure.

Q3: Can heat shrink tubing withstand high temperatures?

A3: Yes, standard tubing handles up to 125°C, while high-temperature heat shrink tubing can withstand up to 260°C.

Q4: What materials are used in heat shrink tubing?

A4: Common materials include polyolefin, PVC, PTFE, and other specialized polymers depending on application requirements.

Q5: Are UL-certified options available?

A5: Yes, UL Heat Shrinkable Sleeve options are available for compliance with international safety standards.

English

English