The Ul Heat Shrinkable Sleeve (also known as Ultra Thin Heat Shrinkable Tube) is a high-performance insulation material made from cross-linked polyolefin.

It is specially designed to provide excellent electrical insulation, strain relief, mechanical protection, and environmental sealing for a wide range of applications.

This ultra-thin wall heat shrink tube offers superior flexibility and quick shrinking performance. When exposed to heat (around 125°C–150°C), it shrinks rapidly to conform tightly around wires, connectors, terminals, and components, forming a durable protective layer.

With UL certification, this Heat Shrinkable Sleeve guarantees reliable quality, safety, and compliance with international standards for industrial and electronic applications.

Technical Specifications

| Item | Description |

|---|---|

| Material | Cross-linked polyolefin |

| Shrink Ratio | 2:1 (custom 3:1 available) |

| Shrink Temperature | Start: 70°C, Full shrink: 125°C |

| Operating Temperature | -55°C to +125°C |

| Dielectric Strength | ≥ 15 kV/mm |

| UL Certification | UL224 VW-1 Approved |

| Flammability | Flame Retardant |

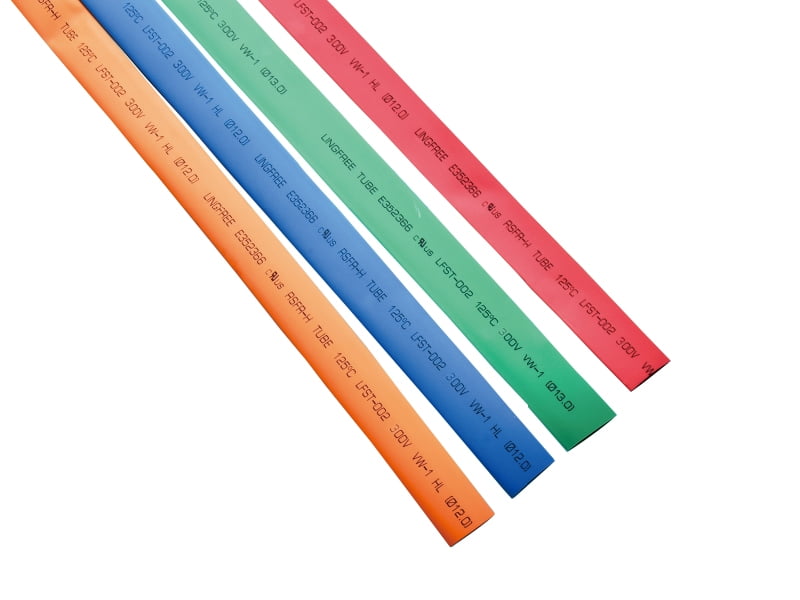

| Color Options | Black, red, yellow, green, blue, transparent (custom colors available) |

| Standard Length | 1.2m / 1.5m / roll or customized |

| RoHS / REACH | Compliant |

Key Features

Ultra Thin & Flexible:

The Ultra Thin Heat Shrinkable Tube provides excellent flexibility and minimal bulk, making it ideal for dense wiring and compact electronic assemblies.

High Electrical Insulation:

Ensures safety and protection for wires, connectors, and electronic components.

Flame Retardant & UL Certified:

Meets UL224 VW-1 standards for flame resistance and reliability.

Durable Protection:

Resists abrasion, chemicals, and mechanical stress while maintaining long-term stability.

Wide Temperature Range:

Performs effectively from -55°C to +125°C, suitable for harsh environments.

Customizable Options:

Available in various colors, sizes, and shrink ratios to meet customer requirements.

Applications

The Ul Heat Shrinkable Sleeve is widely used in various industries, including:

Electrical and Electronic Equipment

Automotive Wiring Harness

Aerospace and Defense

Battery Packs and Chargers

Motors and Transformers

LED Lighting Systems

Consumer Electronics and Communication Devices

It provides reliable insulation and mechanical protection for wires, solder joints, and connectors while enhancing the product’s appearance and durability.

How to Use

Select the proper size – The diameter before shrinking should be about 20–30% larger than the component.

Cut to desired length.

Slide the tube over the wire or connector.

Apply heat using a heat gun or hot air tool until the tube shrinks evenly and tightly.

Allow to cool for a secure, sealed finish.

Advantages

UL & RoHS Certified Quality – Safety and environmental compliance guaranteed.

Space-Saving Design – Thin wall structure ideal for compact circuits.

Easy Installation – Fast shrink rate, excellent adhesion, and smooth finish.

Excellent Cost-Performance Ratio – Durable and affordable insulation solution.

Custom OEM Service – Colors, logos, and packaging can be customized for brand needs.

FAQ

Q1: What does UL certification mean for heat shrink tubing?

A1: UL (Underwriters Laboratories) certification ensures the product meets strict safety, performance, and flammability standards (UL224 VW-1).

Q2: What’s the difference between standard and ultra-thin heat shrinkable tubes?

A2: Ultra-thin tubes have a smaller wall thickness, providing a lighter, more flexible fit for precision electronics.

Q3: Can this sleeve be used outdoors?

A3: Yes. It offers good UV, moisture, and chemical resistance, suitable for outdoor or industrial use.

Q4: What are the available shrink ratios?

A4: Common shrink ratios include 2:1, 3:1, and 4:1, depending on application needs.

Q5: Do you offer custom colors or printing?

A5: Yes, we can print your logo, part number, or batch code upon request.

English

English