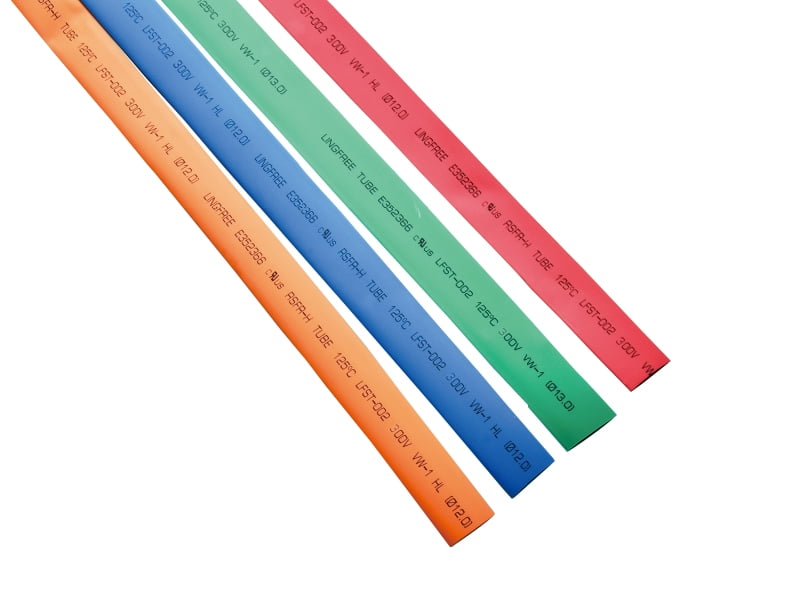

The Ultra Thin Heat Shrinkable Tube is engineered for applications where space, weight, and performance matter most. Featuring extremely low wall thickness and high shrink ratios, this tubing offers precise insulation, mechanical protection, and reliable strain relief for wires, cables, and delicate components. Designed for modern electronics, medical devices, and high-density wiring systems, the ultra thin heat Shrink Tube is an optimal choice for compact and high-performance environments.

Product Overview

The ultra thin shrink tubing is manufactured from cross-linked materials such as polyolefin, fluoropolymer (FEP/PTFE), or PVC. These materials ensure a balance between flexibility, flame retardancy, and electrical insulation. With wall thicknesses ranging from 0.05mm to 0.15mm, the ultra thin wall heat shrink tube fits into tight spaces where standard tubing is too bulky.

Whether you're working on microelectronics or high-density automotive harnesses, our ultra thin insulation tubing provides a professional-grade solution that conforms smoothly to even the smallest components.

Key Technical Characteristics

| Property | Typical Value |

|---|---|

| Wall Thickness | 0.05mm – 0.15mm |

| Shrink Ratio | 2:1, 3:1, 4:1 |

| Operating Temperature | -55°C to 125°C (up to 150°C optional) |

| Dielectric Strength | 300V – 600V |

| Tensile Strength | 10 – 20 MPa |

| Flame Retardancy | UL 224 VW-1 / IEC 60754 compliant |

Applications of Ultra Thin Heat Shrink Tubing

Electronics & Consumer Devices

The ultra thin heat shrink tube is ideal for insulating wires in compact electronics like smartphones, wearables, drones, and laptops. It offers essential abrasion resistance and prevents short circuits without adding bulk.

Automotive Sector

Perfect for tight engine compartments and sensor connections, the ultra thin wall heat shrink tube maintains integrity at high temperatures, protects against vibration, and reduces overall harness diameter in EVs and hybrids.

Medical Equipment

In surgical instruments and diagnostic devices, ultra thin insulation tubing provides reliable dielectric protection without compromising flexibility or biocompatibility.

Aerospace & Defense

Lightweight and durable, this tubing is widely used in avionics systems and mission-critical electronics that demand precise insulation in limited space.

Industrial Automation

For robotics, sensors, and cable assemblies, the ultra thin shrink tubing adds a layer of defense against wear, chemical exposure, and movement stress without limiting flexibility.

Maintenance & Handling Tips

Storage: Keep in a cool, dry place at 15–30°C. Avoid direct sunlight and humidity above 60%.

Installation: Use a calibrated heat gun. Apply heat evenly, maintaining temperatures between 70–150°C.

Handling: Avoid sharp tools or edges that may puncture the thin tubing wall.

Cleaning: Wipe gently with a soft cloth and isopropyl alcohol or mild solvent.

Inspection: Check periodically for signs of discoloration, hardening, or cracking, which may indicate material aging or overheating.

Note: Refer to the manufacturer's technical datasheet for specific material limits, shrink ratios, and certifications.

Why Choose Our Ultra Thin Heat Shrinkable Tube?

Minimal wall thickness for space-saving insulation

Available in multiple shrink ratios (2:1, 3:1, 4:1)

Excellent dielectric and mechanical properties

Compatible with high-density electronics and precision wiring

Meets global flame retardancy and RoHS standards

Ready to upgrade your wiring systems with ultra-precise protection? Our Ultra Thin Heat Shrinkable Tube combines cutting-edge material science with superior performance. Contact us for custom sizes, color options, and bulk pricing.

English

English