Adhesive Lined Heat Shrink Tubing: A Comprehensive Guide

Introduction

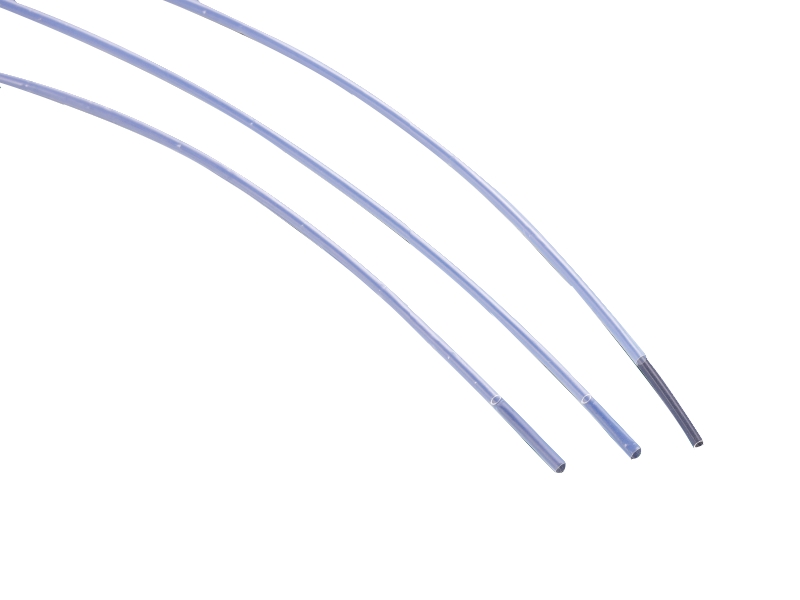

Adhesive Lined Heat Shrink Tubing, also known as dual-wall Heat Shrink Tubing, is a specialized type of tubing designed to provide both insulation and environmental protection for wires, cables, and other components. Unlike standard heat shrink tubing, it features an inner layer of thermoplastic adhesive that melts and flows during the shrinking process, creating a waterproof and strain-relieving seal.

Key Characteristics and Technical Data

Adhesive Lined Heat Shrink Tubing offers several unique properties that make it ideal for demanding applications:

Shrink Ratio: Typically available in 2:1, 3:1, or 4:1 ratios, allowing for significant diameter reduction when heated. For example, a 3:1 ratio means a 3/4" tube will shrink to 1/4".

Operating Temperature Range: Most varieties can withstand -55°C to 125°C (-67°F to 257°F), with some high-temperature versions rated up to 150°C (302°F).

Wall Thickness: Generally ranges from 0.5mm to 2.0mm, with the adhesive layer accounting for approximately 20-30% of total thickness.

Dielectric Strength: Excellent electrical insulation properties, typically 600V to 1000V for standard grades.

Tensile Strength: Ranges from 10MPa to 20MPa depending on material composition.

Flame Resistance: Many types meet UL 224 or other flame retardancy standards, with some achieving VW-1 certification.

Sealing Capability: The adhesive layer creates an IP67 or better seal when properly applied.

Material Composition

The outer layer is typically made from:

Polyolefin (most common, offering good balance of properties)

Fluoropolymer (for high temperature applications)

PVC (less common due to environmental concerns)

The inner adhesive layer usually consists of:

EVA (Ethylene Vinyl Acetate) - most common

Polyamide - for higher temperature applications

Butyl rubber - for excellent moisture resistance

Application Scenarios

Adhesive lined heat shrink tubing finds use in numerous industries and applications:

1. Aerospace and Aviation

Used for wire harness protection in aircraft, where vibration resistance and environmental sealing are critical. Meets standards like AS23053/4.

2. Automotive and Transportation

Protects wiring in harsh environments, particularly in electric vehicles where high voltage insulation is required. Resistant to oils, fuels, and road chemicals.

3. Marine Applications

Provides corrosion protection for electrical connections exposed to saltwater and high humidity environments.

4. Industrial Equipment

Used in factory automation systems, robotics, and heavy machinery where cables are subject to abrasion and chemical exposure.

5. Telecommunications

Protects splice points in outdoor cable runs from moisture ingress, with some types offering UV resistance for aerial applications.

6. Military and Defense

Meets stringent military specifications (MIL-DTL-23053/4) for ruggedized electronic assemblies.

7. Medical Devices

Used in equipment requiring clean, sealed connections that can withstand sterilization processes.

8. Renewable Energy

Protects connections in solar panel arrays and wind turbine systems from environmental factors.

Installation Process

Proper installation is crucial for optimal performance:

Selection: Choose tubing with appropriate diameter (pre-shrink size should be 20-30% larger than the largest component) and shrink ratio.

Preparation: Clean the substrate thoroughly to ensure good adhesive bonding. Remove any sharp edges that might puncture the tubing.

Placement: Slide the tubing over the connection area, allowing sufficient overlap (typically 1.5-2 times the diameter on each side).

Heating: Apply heat evenly using a heat gun (preferred), hot air station, or in some cases, a carefully controlled torch. Optimal temperature is typically 120-150°C (248-302°F).

Verification: Ensure complete shrinkage and adhesive flow. The adhesive should form a continuous bead around both ends.

Maintenance and Care

While adhesive lined heat shrink tubing is designed to be maintenance-free, proper care can extend its service life:

Inspection: Periodically check for cracks, brittleness, or adhesive separation, especially in high-vibration environments.

Cleaning: Use only mild soap and water for cleaning. Avoid solvents that might degrade the material.

Temperature Considerations: Avoid prolonged exposure beyond the rated temperature range.

Mechanical Protection: In high-abrasion areas, consider additional protection like braided sleeving over the heat shrink.

Replacement: If damage is found, the entire section should be replaced rather than attempting spot repairs.

Storage Recommendations

To maintain product integrity before use:

Store in original packaging until ready for use

Keep in a cool, dry place away from direct sunlight

Maintain storage temperature between 10°C and 30°C (50°F to 86°F)

Avoid exposure to ozone sources (e.g., electric motors)

Use within 2 years of manufacture for optimal performance

Standards and Certifications

Quality adhesive lined heat shrink tubing typically complies with various industry standards:

UL 224 (Underwriters Laboratories)

CSA C22.2 No. 198.1 (Canadian Standards Association)

MIL-DTL-23053/4 (Military Specifications)

RoHS and REACH compliance for environmental regulations

ASTM D2671 (Standard Test Methods for Heat-Shrinkable Tubing)

English

English