PTFE Heat Shrinkable Tubing: Properties, Applications, and Maintenance

Introduction

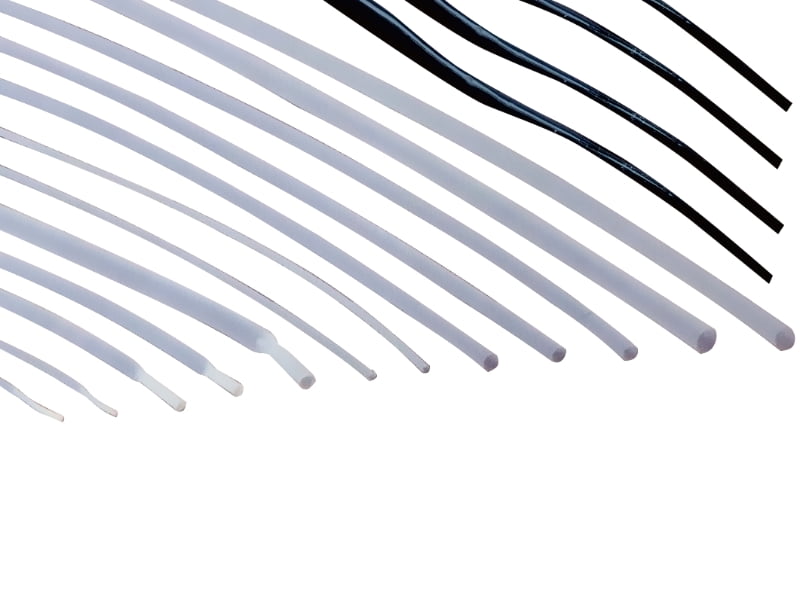

Polytetrafluoroethylene (PTFE) Heat Shrinkable Tubing is a specialized type of fluoropolymer tubing known for its exceptional thermal, chemical, and electrical properties. Unlike conventional PTFE Tubing, heat shrinkable PTFE tubing undergoes radial expansion during manufacturing, allowing it to shrink back to its original dimensions when exposed to heat. This unique characteristic makes it invaluable in industries requiring precision insulation, protection, and sealing.

Key Characteristics of PTFE Heat Shrinkable Tubing

1. Thermal Stability

PTFE heat shrinkable tubing exhibits outstanding thermal resistance, with a continuous operating temperature range of -200°C to +260°C and short-term exposure capability up to 300°C. Its melting point is approximately 327°C, and it maintains dimensional stability even at cryogenic temperatures. The material's thermal conductivity is 0.25 W/m·K, contributing to its excellent insulation properties.

2. Chemical Resistance

The tubing demonstrates near-universal chemical inertness, resisting virtually all industrial chemicals, solvents, and acids, including concentrated sulfuric acid and aqua regia. Its dielectric constant remains stable at 2.1 across a wide frequency range (10Hz to 2.45GHz), with a dissipation factor of 0.0002 at 1MHz.

3. Mechanical Properties

With a tensile strength of 20-35 MPa and elongation at break of 200-400%, PTFE heat shrink tubing offers remarkable mechanical durability. The coefficient of friction is exceptionally low at 0.05-0.10, and its surface energy measures 18.5 dynes/cm, ensuring non-stick performance.

4. Electrical Performance

The material boasts a volume resistivity of >1018 Ω·cm and dielectric strength of >40 kV/mm. Its arc resistance exceeds 300 seconds (ASTM D495), making it ideal for high-voltage applications.

5. Shrink Characteristics

Standard PTFE heat shrink tubing typically achieves a 2:1 shrink ratio, with shrinkage initiation at approximately 175°C and complete shrinkage occurring at 300-320°C. The recovery force measures 0.5-1.5 MPa, ensuring tight conformal fits.

Applications of PTFE Heat Shrinkable Tubing

1. Aerospace and Defense

In aircraft wiring systems, PTFE heat shrink tubing protects sensitive avionics from extreme temperatures (-65°C to 200°C) and hydraulic fluids. Its low outgassing properties (<0.1% TML, <0.01% CVCM per NASA outgassing standards) make it suitable for space applications.

2. Medical Devices

The tubing serves as insulation for electrosurgical instruments, withstanding repeated sterilization cycles (autoclaving at 134°C) while maintaining biocompatibility (USP Class VI, ISO 10993 certified). Its non-stick surface prevents tissue adhesion in minimally invasive surgical tools.

3. Semiconductor Manufacturing

Used in wafer processing equipment, the tubing resists ultra-pure chemicals like HF acid and provides particle-free protection for sensitive components. Its purity level meets SEMI F57 standards with extractable metals <1 ppb.

4. High-Voltage Electrical Systems

As insulation for bus bars and high-voltage connectors (up to 50kV), PTFE tubing prevents corona discharge with its high dielectric strength (>40 kV/mm) and tracking resistance (CTI >600V).

5. Chemical Processing

The tubing protects sensors and instrumentation in aggressive environments, resisting permeation from chemicals like chlorine (permeation rate <0.01 g·mm/m2·day).

Installation and Maintenance Guidelines

1. Proper Installation Techniques

For optimal performance:

Select tubing with 20-30% larger recovered diameter than the substrate

Clean surfaces with isopropyl alcohol (≥99% purity) before installation

Use controlled heat sources (hot air guns at 300-350°C or infrared heaters)

Apply heat uniformly, rotating the part to ensure even shrinkage

Allow gradual cooling to room temperature (20-25°C/min cooling rate)

2. Maintenance Procedures

To extend service life:

Inspect annually for mechanical damage (abrasion >10% wall thickness requires replacement)

Clean with compatible solvents (e.g., perfluorohexane or perfluoroketones)

Monitor for chemical degradation (contact angle measurement <100° indicates surface degradation)

Store in controlled environments (15-25°C, 40-60% RH, away from UV light)

3. Troubleshooting Common Issues

Address typical problems:

Incomplete shrinkage: Increase temperature in 25°C increments up to 350°C maximum

Bubbling: Reduce heating rate to <50°C/min

Delamination: Ensure substrate temperature is >150°C before shrinking

Contamination: Use particle-free handling (cleanroom ISO Class 5 or better)

PTFE heat shrinkable tubing represents the pinnacle of performance in critical insulation and protection applications. Its unique combination of properties enables solutions where other materials fail, particularly in extreme environments. Proper selection, installation, and maintenance ensure optimal performance throughout its service life.

English

English