Ultra Thin Heat Shrink Tube is a specialized protective tubing solution designed to offer exceptionally thin insulation while maintaining excellent durability, flexibility, and heat resistance. With wall thicknesses as low as 0.1mm, this ultra thin wall heat shrink tubing is ideal for compact electronic applications where space-saving, lightweight insulation is critical.

Whether you are working in the PCB assembly, medical electronics, wire harnessing, or high-density communication systems, our micro heat shrink tubing offers a precise fit, secure wire protection, and long-lasting performance.

Key Features

Ultra Thin Wall Design: Thickness as low as 0.1mm, perfect for tight spaces and fine wires.

Flame Retardant and RoHS Compliant: Safe and environmentally friendly, ideal for electrical heat shrink tubing needs.

Excellent Flexibility: Easy to install, bend, and wrap, even around complex shapes.

Wide Range of Shrink Ratios: Available in 2:1, 3:1, and custom options for different shrink levels.

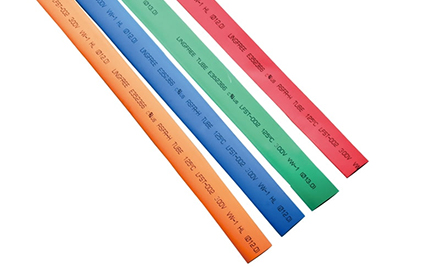

Transparent and Colored Options: Choose from transparent heat Shrink Tubes for visibility or colored ultra thin shrink tubing for coding and aesthetics.

High-Performance Material: Made of polyolefin, this flexible heat shrink tube is both chemical resistant and abrasion resistant.

Low Shrink Temperature: Starts shrinking at around 70°C, fully recovers by 110°C, suitable for heat-sensitive components.

High Electrical Insulation: Effective barrier for wire protection, signal shielding, and circuit insulation.

Custom Sizes Available: Tailored inner diameters and lengths to suit various small diameter heat shrink tube requirements.

Applications

Wire Protection Heat Shrink Tube for thin conductors

Heat Shrink Tube for PCB components and microchips

Heat Shrinkable Wire Sleeve for headphone cables, signal lines

Medical equipment and sensor encapsulation

Automotive wiring and labeling

Aerospace and communication modules

Why Choose Our Ultra Thin Heat Shrinkable Tubing?

We provide high-performance heat shrink tubing products with fast turnaround, bulk supply, and custom printing/packaging options. Whether you need transparent, colored, or custom-shaped tubing, we have the capability to deliver what your project requires.

All our thin heat Shrink Sleeves meet international standards and are tested for mechanical strength, thermal aging, and electrical safety.

Available Specifications

Shrink Ratio: 2:1 / 3:1

Inner Diameter: 0.5mm to 30mm (before shrink)

Wall Thickness: As low as 0.1mm

Colors: Black, Transparent, Red, Blue, Yellow, Green, etc.

Operating Temperature: -55°C to +125°C

Shrink Temperature: ≥70°C

Material: Polyolefin (Halogen-Free options available)

Certification: RoHS, UL (optional), REACH

Get a Custom Quote

Looking for custom heat shrink tubing? We support OEM & ODM services to meet your specific technical and branding requirements. From bulk rolls to cut-to-length solutions, we ensure you get exactly what your application needs.

FAQ

1. What is an ultra thin heat shrink tube?

An ultra thin heat shrink tube is a protective tubing with a very thin wall (as low as 0.1mm) that shrinks when heated to provide insulation, mechanical protection, or bundling.

2. What are the typical applications of ultra thin heat shrink tubing?

It's commonly used in compact electronic assemblies, PCB protection, wire identification, lithium battery packs, medical devices, and miniature components.

3. What is the shrink ratio of the ultra thin heat shrink tube?

Standard shrink ratios include 2:1 and 3:1. Upon heating, the tube shrinks to a predetermined size to fit snugly around the object.

4. What temperature is required to shrink the tube?

Most ultra thin heat shrink tubes begin shrinking around 70°C to 110°C, depending on the material.

5. Is the tubing flame retardant or RoHS compliant?

Yes, many ultra thin heat shrink tubes are made from flame-retardant polyolefin or fluoropolymer and comply with RoHS environmental standards.

6. Can it be customized for size, color, or printing?

Yes, customization options include inner diameter, wall thickness, color coding, and printing for identification purposes.

7. Is the ultra thin heat shrink tube suitable for high-voltage applications?

Due to its minimal thickness, it's ideal for low-voltage and signal-level applications. For high-voltage protection, thicker alternatives are recommended.

8. Can it be used outdoors or in harsh environments?

Select ultra thin tubing variants with UV resistance and waterproof properties are suitable for outdoor or semi-harsh environments.

9. What materials are used in ultra thin heat shrink tubing?

Common materials include cross-linked polyolefin, PTFE, PVDF, and FEP for their flexibility, thermal stability, and dielectric strength.

10. How is ultra thin heat shrink tubing packaged and supplied?

It is usually supplied in reels, spools, or pre-cut lengths depending on the quantity and user requirements.

English

English