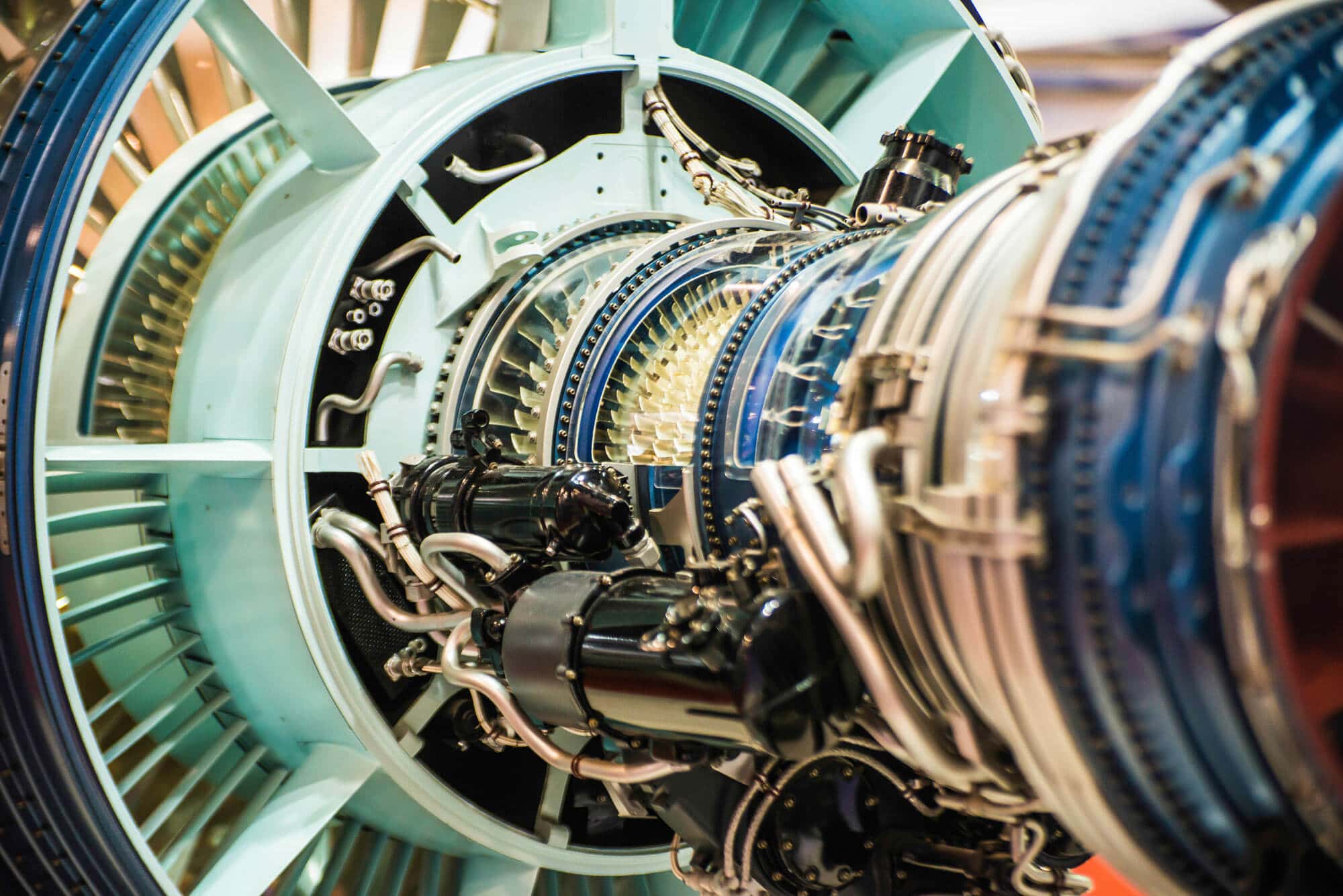

In the aerospace industry, where performance and precision are non-negotiable, every component must withstand extreme conditions while meeting the strictest safety and compliance standards. Our client, a well-known aerospace parts manufacturer, needed a thermal insulation and abrasion-resistant solution to protect internal wiring systems for next-generation aircraft.

Customer Background

The client specializes in producing high-density wiring harnesses and critical control components used in both commercial and military aircraft. These components are frequently subjected to:

High-temperature environments (up to 260°C)

Constant vibration

Chemical exposure (hydraulic fluids, oils)

Stringent weight and space limitations

Ensuring the long-term reliability of cable assemblies in such conditions required a solution that balances mechanical protection, thermal resistance, and lightweight design.

Project Challenges

The client faced several key challenges:

Thermal Endurance: Internal engine bay areas could reach temperatures of 200–260°C.

Abrasion and Chemical Resistance: Wiring exposed to physical contact and corrosive fluids.

Compliance with Aerospace Standards: Materials needed to meet MIL-I-23053, UL, RoHS, and flame-retardant requirements.

Weight Control: Lightweight materials were essential to avoid increasing the aircraft’s operational load.

Our Solution

After careful evaluation, we provided a combination of Silicone-Coated Fiberglass Sleeving and PTFE Heat Shrink Tubing that offered:

High Temperature Resistance: Withstanding continuous operation at up to 260°C

Excellent Mechanical Strength: Fiberglass base resists fraying, vibration, and wear

Non-reactive Surface: PTFE coating prevents chemical degradation

Flame Retardant and Low Smoke: Ideal for cabin and engine bay applications

Custom Sizing & Cut Lengths: Tailored to fit narrow installation areas precisely

We also provided pre-cut lengths and color-coded sleeves to improve installation efficiency and prevent errors during assembly.

Material Details

| Material | Key Properties | Application |

|---|---|---|

| Silicone-Coated Fiberglass Sleeve | Heat resistance up to 260°C, flexible, flame retardant | Cable bundling in engine bay |

| PTFE Heat Shrink Tubing | Chemically inert, low friction, thin-wall | Connector insulation and EMI shielding |

| FEP Sleeving (Optional) | Transparent, high-performance plastic | Visible inspection areas |

Customer Feedback

“Your thermal insulation solution was key to passing our engine bay qualification tests. We were particularly impressed by the durability of the fiberglass sleeves and the way your team supported us with fast prototyping and flexible customization.”

— Project Engineer, Avionics Division

Thanks to our rapid response, technical consulting, and high-quality materials, the customer successfully integrated the sleeving solution into their production line within 4 weeks — reducing assembly errors by 20% and improving overall wiring harness durability by 35%.

Why Choose Us for Aerospace Projects?

Aerospace-Grade Materials: All products tested under extreme stress conditions

Strict Quality Control: Full traceability, batch testing, and dimensional precision

Custom Engineering Support: From design consultation to final delivery

Global Compliance: Products meet major international standards including RoHS, UL, MIL-Spec

Let’s Work Together

Whether you're designing next-gen unmanned systems, satellites, or commercial aircraft, we offer custom protective sleeving solutions that help you fly higher, safer, and longer.

Contact us today for samples, datasheets, and expert consultation on aerospace insulation materials.

English

English