busbar insulation sleeves are essential components in electrical systems, offering reliable protection for busbars, which are critical conductors used in electrical power distribution. Designed to prevent environmental damage, electrical faults, and mechanical wear, these sleeves ensure the safe and efficient operation of electrical systems in various applications, from high-voltage power distribution to industrial machinery and renewable energy setups.

Product Features

1.Superior Electrical Insulation

Busbar insulation sleeves provide excellent dielectric properties, effectively preventing electrical leakage and short circuits. These sleeves are designed to withstand high voltages, offering maximum electrical protection and ensuring the safe distribution of electricity in power systems.

2.Heat Shrink Technology

Many busbar insulation sleeves are made from heat-shrinkable materials. The heat-shrink process allows for easy installation—just apply heat to make the sleeve shrink and fit tightly around the busbar. This ensures a secure, durable fit, providing optimal protection against external damage.

3.Durable and Resistant

These sleeves are designed for durability, offering resistance to abrasion, chemicals, moisture, and UV radiation. This robustness ensures long-term protection for your electrical systems, reducing the frequency of maintenance and replacements.

4.Customizable Sizes and Lengths

Busbar insulation sleeves are available in various sizes and can be customized to fit different busbar diameters and installation needs. This flexibility makes them suitable for a wide range of busbar designs and system configurations.

5.Temperature Resistance

Available in a variety of materials, busbar insulation sleeves are designed to operate across a wide temperature range—from industrial environments to high-temperature settings—ensuring reliable insulation under various conditions.

Key Benefits

Enhanced Electrical Safety

Busbar insulation sleeves prevent accidental contact with live conductors, protecting operators and maintenance personnel from electric shocks and reducing the risk of electrical faults that could lead to equipment damage or fires.

Improved Reliability and Durability

By providing a long-lasting protective barrier, these sleeves protect busbars from wear and tear, moisture, dust, and chemicals, ensuring long-term reliability and reducing maintenance costs.

Quick and Easy Installation

With heat-shrinkable sleeves, the installation process is simplified. Just apply heat using a heat gun or oven, and the sleeve will shrink to form a tight, durable fit, ensuring hassle-free installation.

Environmental Protection

These sleeves offer excellent resistance to UV radiation, chemicals, and extreme temperatures, making them suitable for both indoor and outdoor applications, enhancing the overall performance of your electrical system.

Cost-Effective Solution

The combination of a long service life, minimal maintenance needs, and easy installation makes busbar insulation sleeves a cost-effective choice. They reduce both upfront and long-term operational costs, providing excellent value for money.

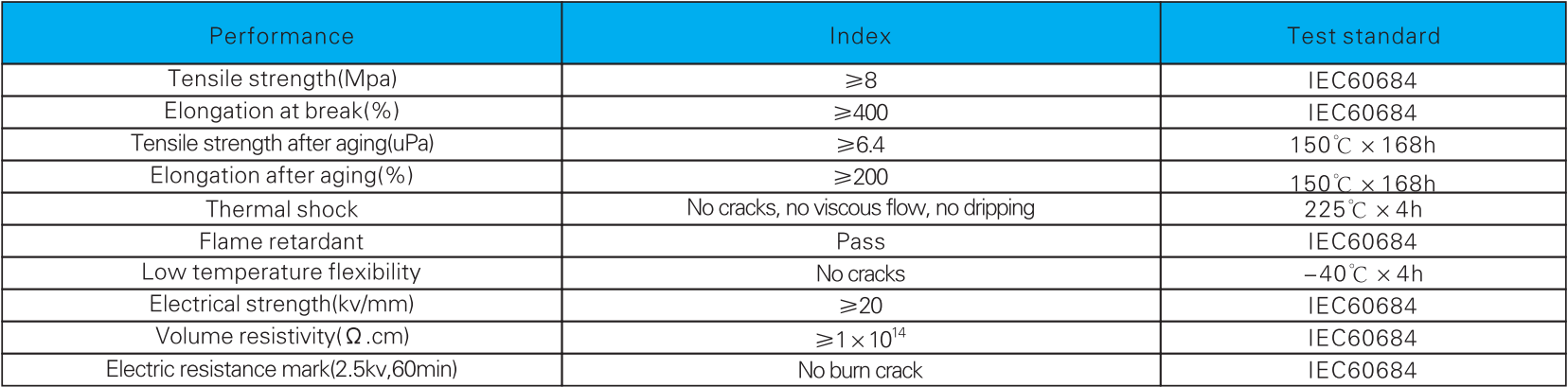

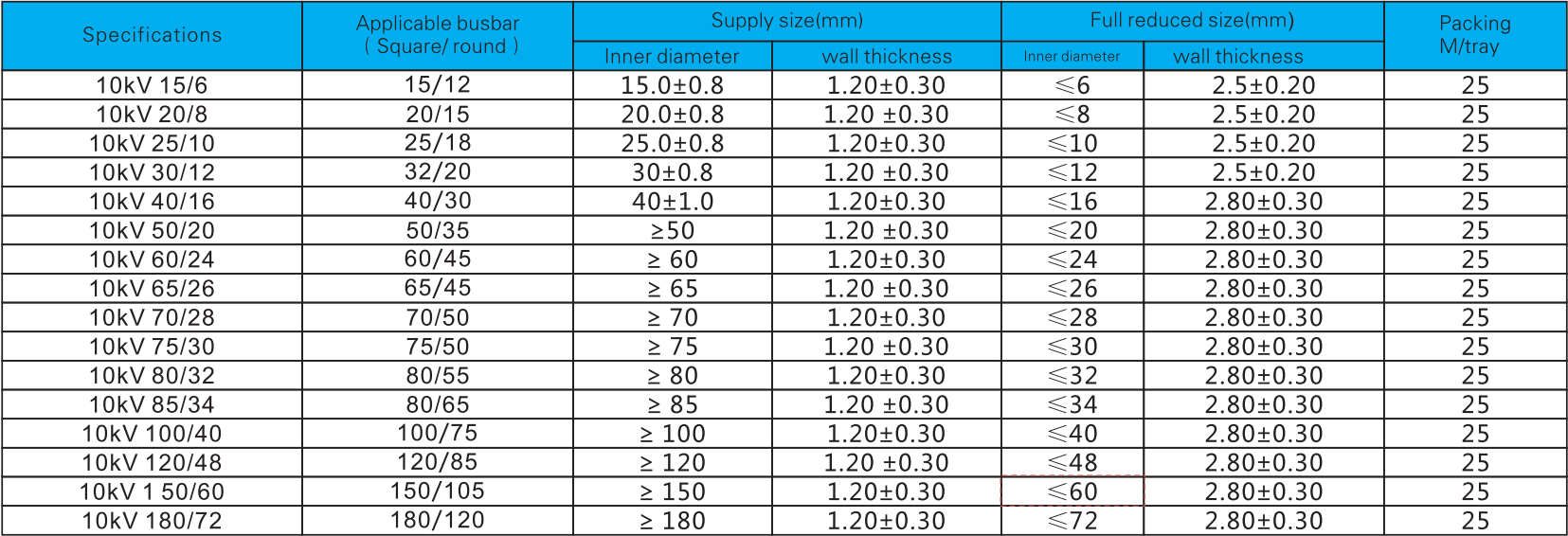

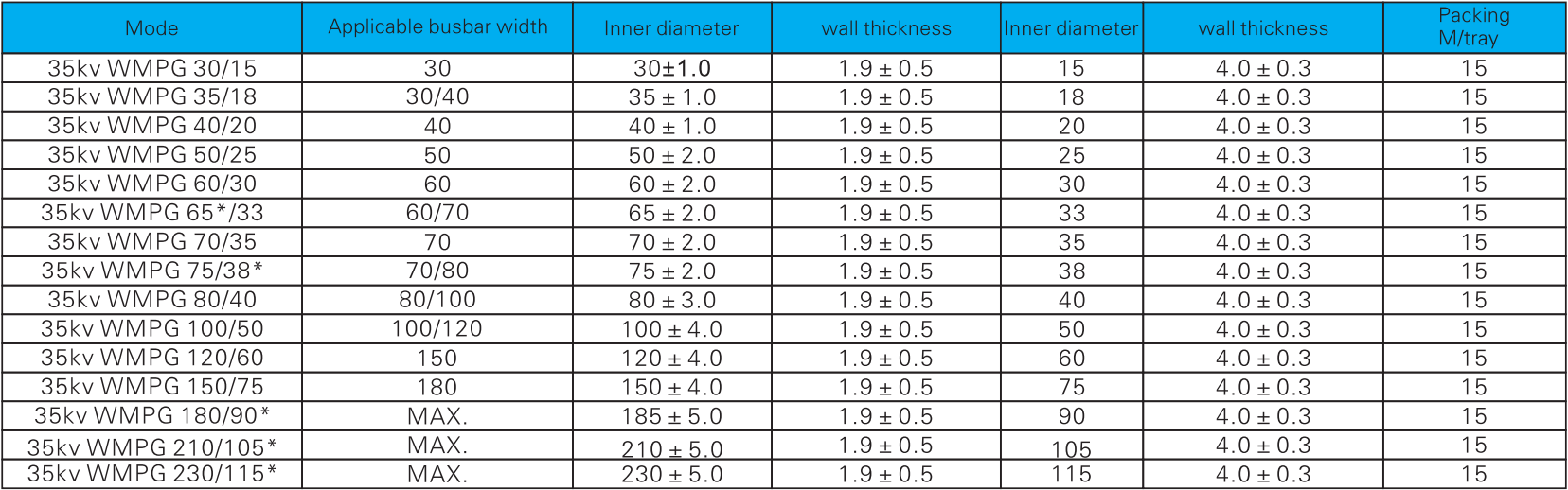

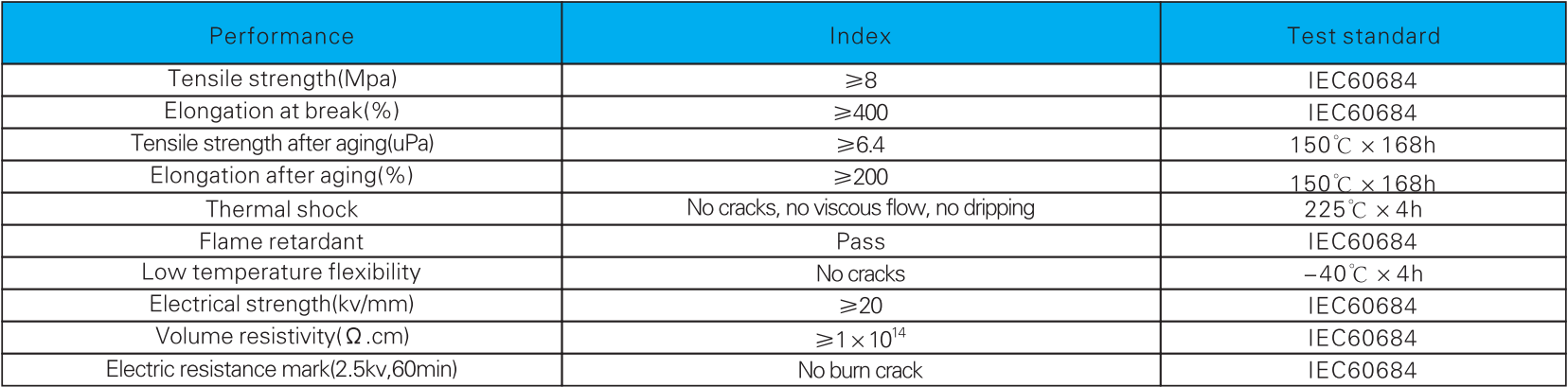

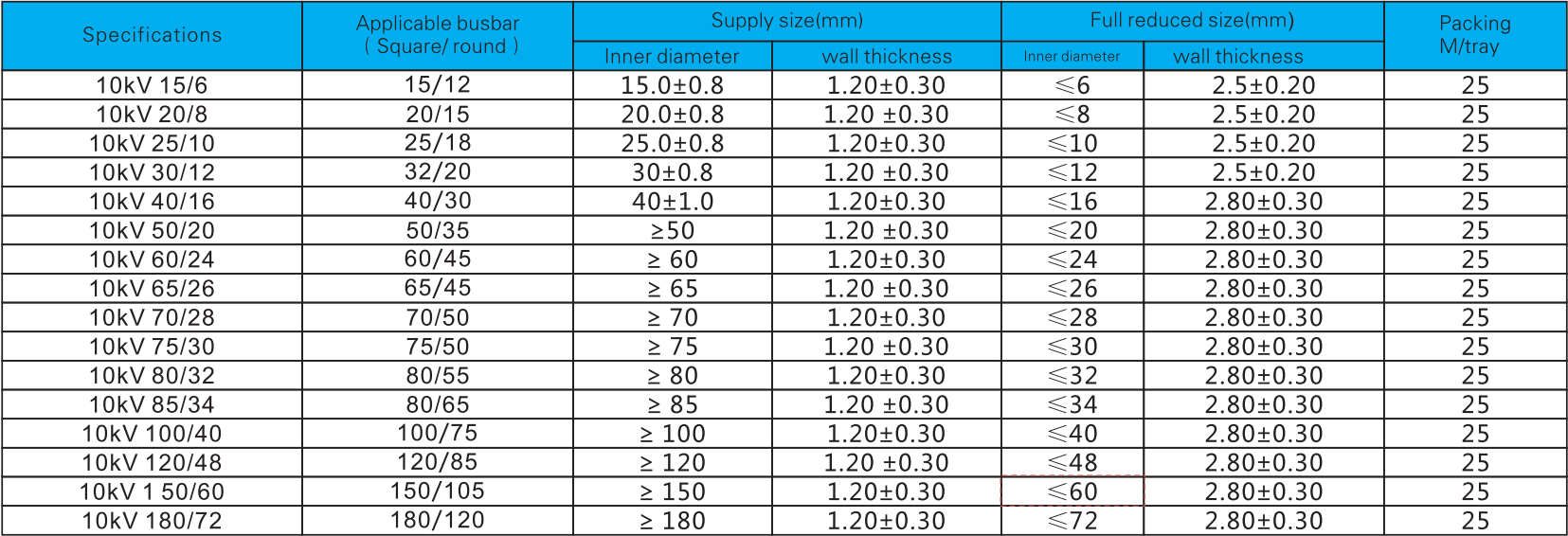

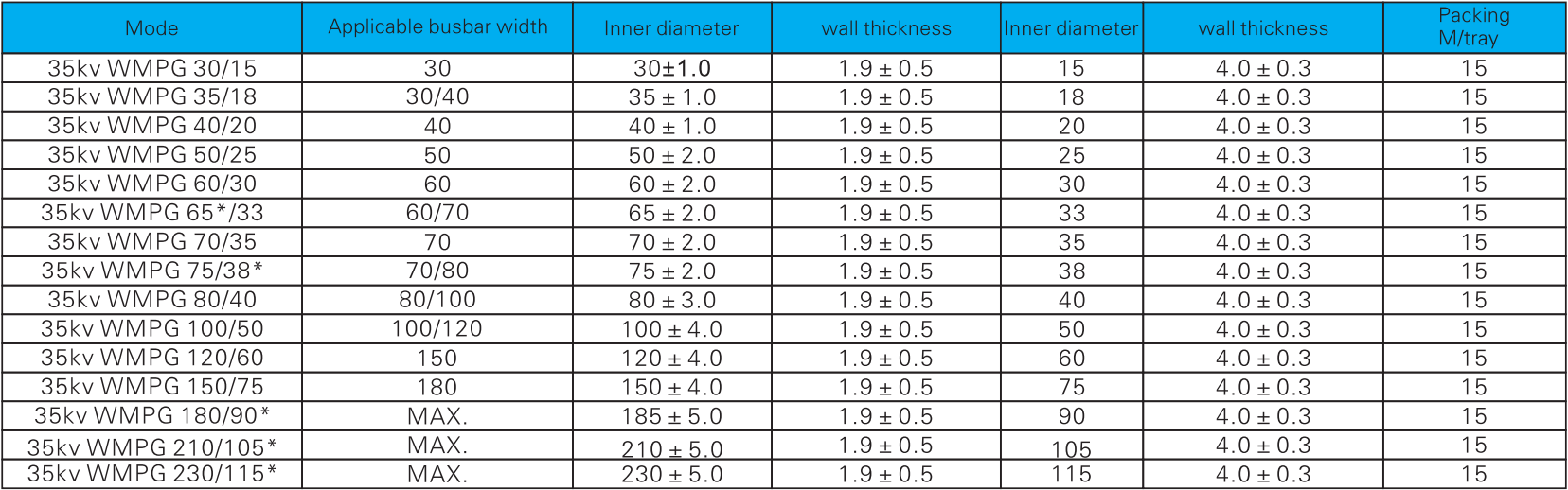

Specification

Table 1:10KV

Table 2:35KV

Applications

Busbar insulation sleeves are versatile and used in a variety of industries, including:

Power Distribution Systems: Protecting busbars in substations, power plants, and electrical switchgear.

Industrial Machinery: Ensuring safe operation in manufacturing plants by insulating busbars in heavy-duty machinery and control panels.

Renewable Energy: Protecting busbars in solar power systems and wind turbines to ensure safe transmission of electricity.

Electric Vehicles (EVs): Used in the electrical systems of electric vehicles to provide insulation for busbars in battery packs and motor controllers.

Residential and Commercial Systems: Offering protection in electrical panels, circuit breakers, and other electrical infrastructure in commercial and residential applications.

Installation Process

Preparation: Ensure the busbar is clean and free of contaminants such as dust, oil, or grease before applying the insulation sleeve.

Sizing: Choose the appropriate size of insulation sleeve based on the busbar’s diameter. Ensure the sleeve’s shrink ratio is compatible with the busbar’s size.

Installation: Slide the insulation sleeve over the busbar. For heat-shrinkable materials, apply heat using a heat gun or oven until the sleeve tightly conforms to the busbar.

Cooling and Inspection: After installation, allow the sleeve to cool, then inspect for any potential areas needing additional shrinkage. Ensure no gaps or air pockets are left.

FAQ:

What are busbar insulation sleeves?

Busbar insulation sleeves are protective coverings designed to insulate and protect busbars—metallic conductors used in electrical power distribution systems. These sleeves help prevent electrical faults, reduce the risk of short circuits, and protect busbars from environmental damage like moisture, dust, and chemical exposure.

Why are busbar insulation sleeves important?

Busbar insulation sleeves are crucial for ensuring electrical safety by preventing accidental contact with live conductors, reducing the risk of electric shocks and electrical fires. They also protect busbars from physical damage, corrosion, and wear, thus improving the reliability and longevity of electrical systems.

How are busbar insulation sleeves installed?

Busbar insulation sleeves are typically installed by sliding them over the busbar and applying heat (for heat-shrinkable sleeves). The heat causes the sleeve to shrink and tightly fit around the busbar, providing a secure and durable protective covering. Non-shrinkable options may simply slip over the busbar and be secured with adhesive or clips.

What are the main advantages of using heat-shrinkable busbar insulation sleeves?

Heat-shrinkable busbar insulation sleeves offer several advantages:

Tight, custom fit: They conform precisely to the shape of the busbar when heated.

Durability: They provide long-lasting protection against mechanical stress, moisture, and environmental factors.

Ease of installation: The shrinkage process is quick and easy, requiring only a heat gun or oven.

Improved insulation properties: They create a strong insulating barrier around the busbar.

What is the voltage rating of busbar insulation sleeves?

The voltage rating of busbar insulation sleeves varies based on the material and the application. Typically, they can handle voltages up to 36 kV, but high-performance versions, such as those made with fluoropolymer or silicone, can support even higher voltage ratings, making them suitable for demanding applications.

Can busbar insulation sleeves be used in high-temperature environments?

Yes, busbar insulation sleeves made from materials like silicone rubber or fluoropolymer are specifically designed to withstand high temperatures. Silicone, for instance, can endure temperatures ranging from -60°C to 200°C, making it suitable for high-temperature environments like industrial machinery or power plants.

Are busbar insulation sleeves customizable?

Yes, busbar insulation sleeves can be customized in terms of length, diameter, material type, and shrink ratio to fit the specific requirements of a busbar. Customization ensures that the sleeves perfectly match the size and application of the busbar, providing optimal insulation and protection.

English

English